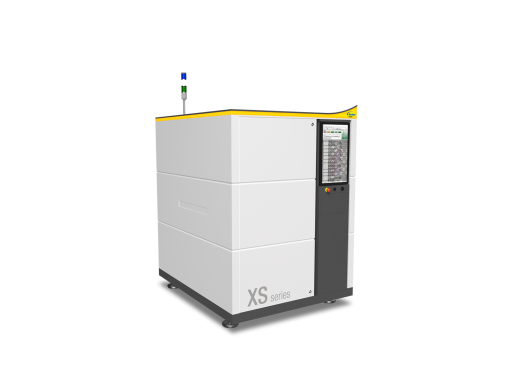

XS Series

The XS-platform series is a small-footprint high-resolution automated X-ray inspection system concept designed for sophisticated high-speed inspection of semiconductor samples, wire bonds and PCB-assembly boards for single/multipanels or samples in trays. The inspectable applications range from component level inspection to mid-sized SMT boards.

| Category | Inline X-RAYs |

|---|---|

| Our solution | Inspection in SMT, Testing and inspection in eMOBILITY |

| Supplier | Matrix |

The capacity of the device is the best fit for CT inspection of small and middle sized batches, usage in laboratory environment, sample production or fault analyses.

The applications range from consumer electronics and automotive li-ion batteries, component level inspection for wire bonds, micro-solder-joints on PCB‘s, casting parts and semiconductors.

Main features and benefits of the device

- High speed AXI system with minimum footprint for inline setups

- Microfocus / Submicron X-ray tube (sealed tube / maintenance free)

- Resolution down to <1µm

- Multiple programmable motion system with servo drives

- Digital CMOS flatpanel detector Automatic grey-level and geometrical calibration

- Barcode reader and program loading

- Full product traceability via customized MES-Interface

Related categories

We offer 3D AOI (Automatic Optical Inspection) produced by the company Saki Corporation. The Saki AOI machines are unique with their 3D technology...

The completeness of our offer is crowned with the production of single purpose machines, robotic workstations and manufacturing lines.

Saki’s 2D AOI systems include a large telecentric lens to capture the clearest images with no blind spots. The system corrects for brightness...